Fabrication

Pipe - Skids - Modules

Shop Location:

La Porte, TX

Shop Size

40,500 sq. ft. Total Shop Space Under Roof of which 15,000 sq. ft. Is Under Hook, with 5 acres of outside storage. Shop has dedicated alloy and carbon bays for complete material segregation. BCI's fabrication shop has rail access and is strategically located between Port of Houston's Barbours Cut and Bayport Terminals.

Shop Equipment

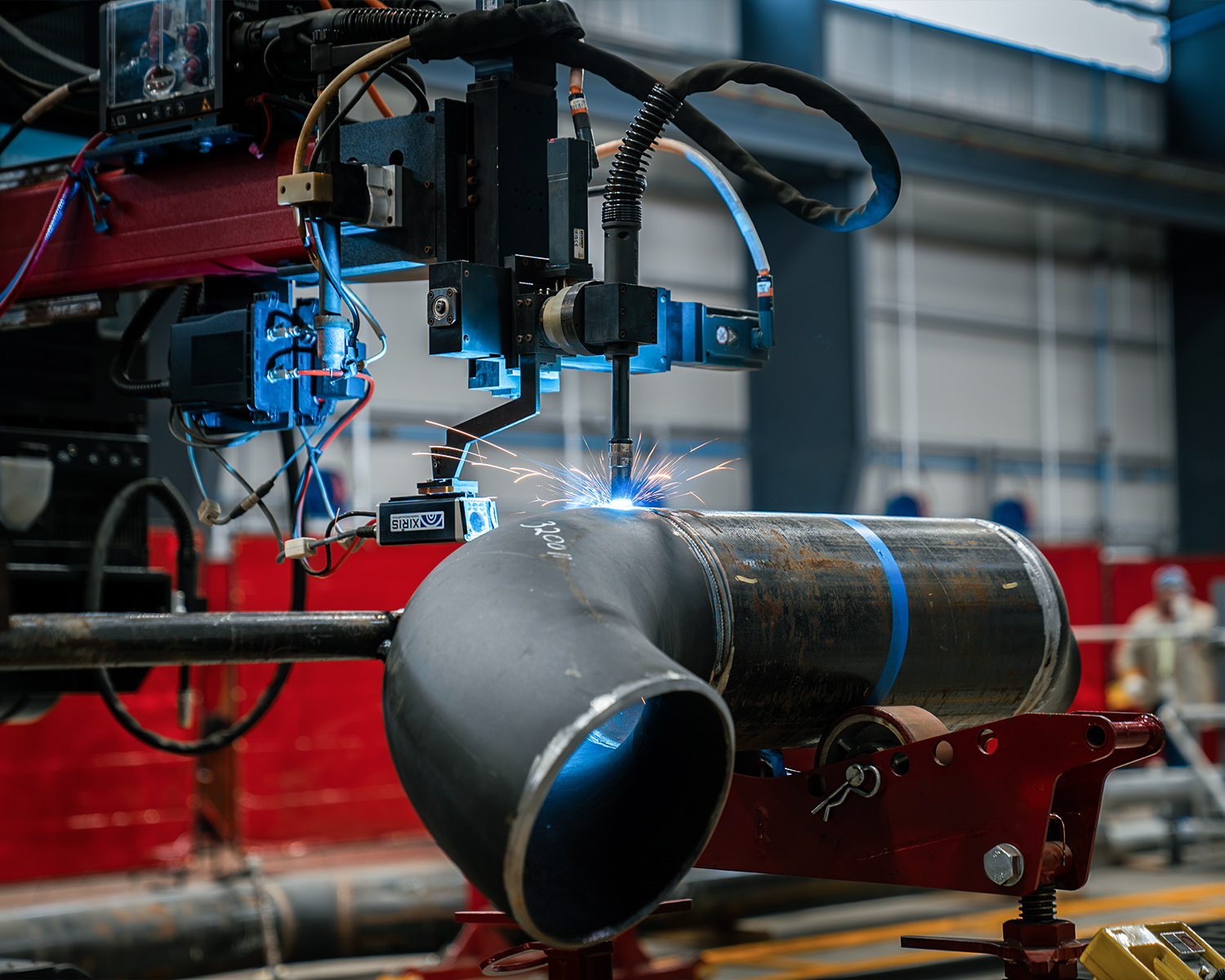

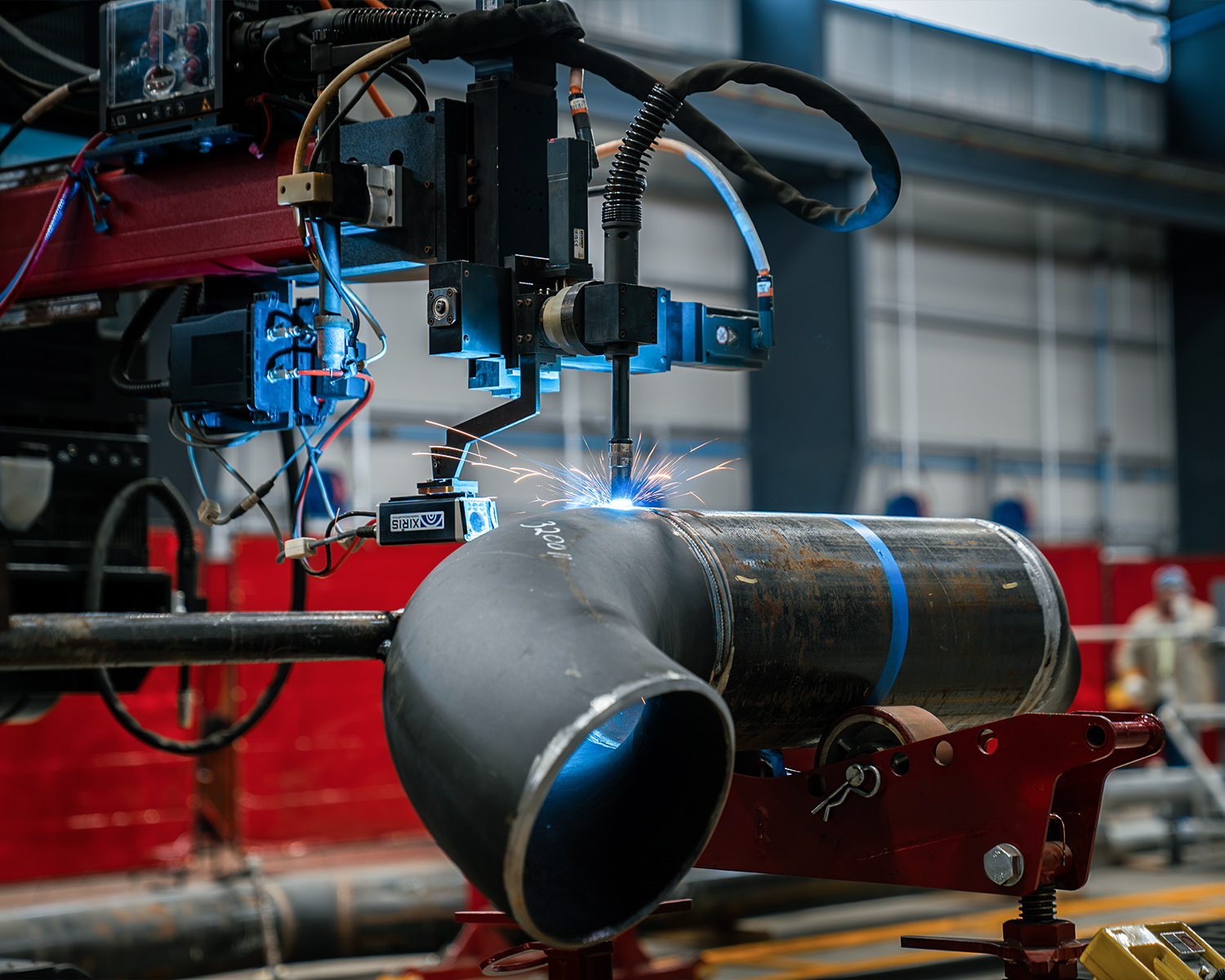

- Watts Mueller 6-Axis CNC Automated Plasma Pipe Profiler w/Mechanized 45’ Bed

- Redi2Weld Dual Bay Automated Welding System with Hot Wire GTAW/FCAW Combo

- 20 Welding Stations with Miller PipeWorx Multi Process Welding Machines (GMAW/FCAW) or Miller Syncrowave Welding Machines (GTAW)

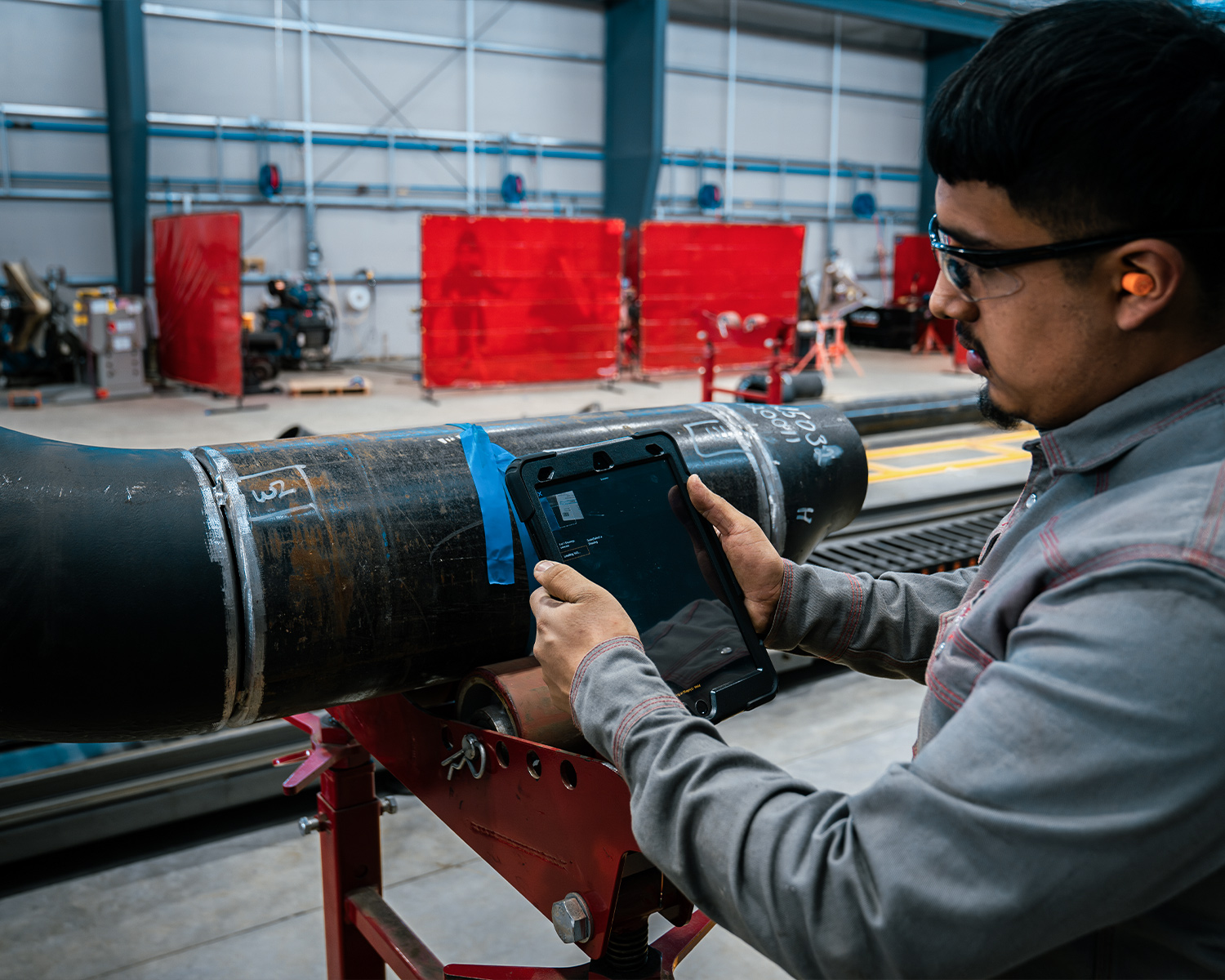

- MSUITE spool tracking software to provide real time traceability and progress updates for each project

- Turning Positoners from 500# to 3,000#

- 2 - 15 Ton Overhead Cranes

- 5,000# and 12,000# Forklifts

- Hydrotesting and NDT Area

- Pickle and Passivation Area

Materials Fabricated

- All Carbon Steels, Including Low Temperature Piping Specs

- All Stainless Steels, Including 304/304L, 316/316L, Duplex and Super Duplex

- All Chrome P Numbers (Heat Treating Outsourced with Strategic Partner)

Shop Manpower and Output

- 30 craftsmen on 1 shift, available to work 60 craftsmen on 2 shifts and 90 craftsmen on 3 shifts.

Factored Diameter Inch (FDI) Welding Output:

- 860 FDI per day on 1 shift

- 1,720 FDI per day on 2 shifts

- 2,580 FDI per day on 3 shifts

NDT Capabilities (3rd Party)

- Conventional Radiography

- Ultrasonic Conventional

- Ultrasonic Phased Array

- Ultrasonic Time of Flight Diffraction

- Magnetic Particle

- Dye Penetrant

Coatings (3rd Party)

- Standard Sandblast and 1-2-3 Coat Systems

- Fusion Bonded Epoxy Coatings

- Powder Coatings

- Oxygen Clean Systems

Purchasing

- BCI is strategically partnered and located across the street from several of the nation’s largest pipe, valve and fitting suppliers.

Pipe Fabrication Management Team

- Full Time Director of Fabrication

- Full-Time Shop Manager

- Full-Time CWI Inspector

- Full-Time Material Manager

- Full-Time Shop Inspector (non-CWI)

Codes Worked and Certifications

- ASME B31.1

- ASME B31.3

- API 1104

- ASME BPVC “R” and “S” Stamp Authority

- All welders certified to ASME Section IX and BCI Welding Procedure Specifications

- All BCI Welding Procedure Specification have accompanying Procedure Qualification Records